Case: 3D printed super duplex steel - the offshore impeller reinvented

Equinor is the energy giant determined to be the energy supplier of the future. Super-duplex stainless steel is the materials family whose properties are a superior fit for the demanding offshore and marine industries. Sandvik is the first company on the market to successfully 3D print super duplex components at a standard that doesn’t just meet, but outperforms that of several traditionally manufactured counterparts. The result is a pallet-teasing sample of the impact super duplex and AM could have on – and under – the sea.

The offshore and marine segments are without a doubt two of the best examples of industries that take the demands for durability, safety, and corrosion resistance to the next level. Over the years and between the innovations of the materials experts at Sandvik Additive Manufacturing, there’s one material family that stands out in terms of catering to the needs of these extreme environments – namely duplex, super-duplex, and hyper-duplex steel.

Super duplex in additive manufacturing – a gamechanger offshore

Sandvik and part subsidiary BEAMIT Group announce unique capability to produce AM components in Osprey® 2507 – known and trusted for its excellent corrosion resistance and durability.

Thanks to its excellent resistance to corrosion and outstanding mechanical strength, super-duplex stainless steel has previously been successfully used offshore in the shape of seamless tubes and bars. Now it’s finally possible to 3D print components in any shape – in the super-duplex stainless-steel metal powder Osprey® 2507 super-duplex metal powder. Gisle Rørvik, Advisor Materials Technology at Equinor: “Sandvik is a key manufacturer and developer for materials used in our systems – especially the corrosion resistant ones. It’s essential to exploit and develop the 3D printing capabilities of the major oil and gas alloys, including super-duplex steel. Our main challenges are to ensure robust selection and quality control of materials to withstand several corrosion, wear, and hydrogen embrittlement mechanisms, as well as adequate structural performance to avoid ductile, brittle or fatigue fractures”.

Sandvik is a key manufacturer and developer for materials used in our systems. It’s essential to exploit and develop the 3D capabilities of the major oil and gas alloys, including super-duplex stainless steel.

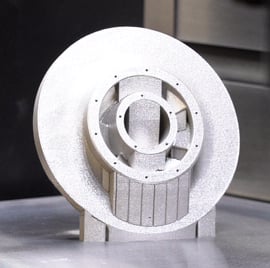

Sandvik has been driving the materials evolution for almost 160 years. All the while delivering materials fit for use in the most demanding industries, it’s no exaggeration to say that creating customized materials that fit the need of any business, is part of our DNA. We could ask you to imagine the impact this fact could have - but there’s no need for that. Instead we give you: the 3D printed impeller in Osprey® 2507-AM super-duplex powder. Rather modest in appearance, impellers are inverted propellers often found in shafts, valves, and casings, where they typically drive fluids through pipes – not seldomly so in highly corrosive offshore and marine environments.

The results are extremely satisfying. We’ve created a 3D printed component that outperforms several conventional manufacturing technologies.

Teaming up with Equinor, leveraging on their position as an experienced energy supplier to create a more sustainable industry, and Eureka Pumps AS – one of the industry-leading pump supplier for the offshore and marine segment – Sandvik contributed with the Osprey® 2507-AM super-duplex powder and additive manufacturing technology to turn this idea into reality. Nikhil Dixit and André Larsson are R&D Engineers at Sandvik Additive Manufacturing, and collaborated on the design of the 3D printed impeller. Dixit says:

“This project was quite a challenge to begin with as several researchers in the field had reportedly tried, and failed, to develop the printing parameters for super-duplex steel. But the development went faster than I ever expected. We were very pleased to find we achieved a fully dense material (>99,9%) and crack-free results just from printing – even before post-processing. When examining the test specimens, the results were extremely satisfying. I’m proud to say that through additive manufacturing, we’ve created a component in Osprey® 2507-AM super-duplex powder that actually outperforms several conventional manufacturing techniques.”

We are definitely starting to see the benefits of additive manufacturing [...] reducing lead and down times, optimized cunction and performance optimized function

Facts

Outcome

A faster, lighter, more cost-efficiently manufactured impeller

Designers

Eureka Pumps AS

Material

Osprey® 2507 super-duplex stainless steel

Additive technology

Powder Bed Fusion Laser

Post processing

Heat treatment and blasting

The impeller is a concrete piece of evidence that additive manufacturing is in fact a perfect match for the offshore and marine industries. Just imagine 3D printed spare parts produced just in time, as opposed to keeping large quantities in stock – just in case. Imagine not only being able to create complex geometries, but optimizing capacity and decreasing weight as well. Gisle Rørvik again: “We are definitely starting to see the benefit and potential of additive manufacturing, both in terms of replacement or repairing of obsolete parts, as well as in reducing lead and down times, optimized function and performance of new parts, reduced environmental footprint, and the gradual reduction of our physical inventory and establishment of a ‘digital supply chain and warehouse”. A new dawn is on the horizon. Are you impelled to act, yet?

Download material datasheet