Material data: Osprey® 2507 super-duplex stainless steel

General description

Osprey® 2507 is a super-duplex (austenitic-ferritic) stainless steel powder manufactured by inert gas atomization. The alloy is characterized by, for example:

- Excellent corrosion resistance in chloride environments (PREN~ 43)

- Excellent mechanical properties

- High resistance to general corrosion

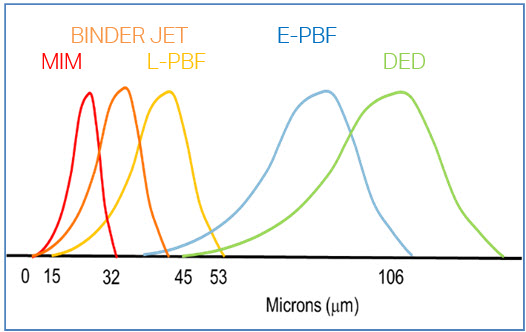

Osprey® 2507 metal powder is available in a range of customized powder sizes suitable for:

- Binder Jet (AM)

- Powder Bed Fusion (AM)

- Direct Energy Deposition (AM)

- Metal Injection Moulding (MIM)

Chemical composition

Chemical composition

| Fe | Cr | Ni | Mo | Mn | Si | N | Cu | C | P | S |

|---|---|---|---|---|---|---|---|---|---|---|

| Balance | 25.0 | 7.0 | 4.0 | <1.2 | <0.8 | 0.30 | <0.50 | <0.030 | <0.035 | <0.015 |

Powder morphology

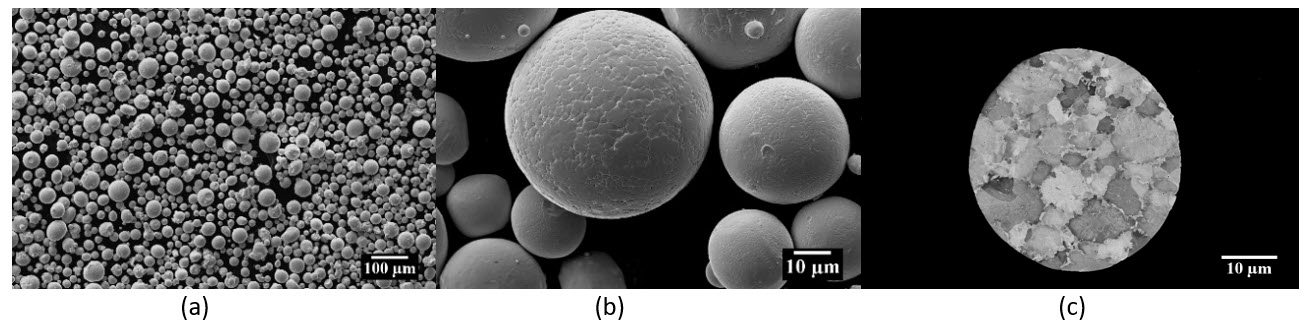

SEM micrographs of Osprey® 2507 a) -53 +15 µm powder with a spherical morphology, b) smooth surface and low level of powder satellites and c) micrograph of powder in cross-section, in back scatted electron mode, highlighting the fine cellular structure.

Powder size distribution

Available in a range of customized powder sizes suitable for different additive manufacturing technologies:

Metal Injection Moulding

- < 32 µm, < 22 µm, <16 µm, < 10 µm and < 5 µm

Binder Jet

- < 45 µm, < 38 µm, < 22 µm, < 16 µm

Laser beam - Powder Bed Fusion, (L-PBF)

- e.g. 53 to 15 µm and 45 to 20 µm

Electron Beam - Powder Bed Fusion, (E-PFB)

- 106 to 45 µm

Direct Energy Deposition (DED)

- 150 to 53 µm and 90 to 45 µm

Other powder size range distributions are available by request.

Mechanical properties

Tensile properties

| Condition | Direction | Temperature | Proof strength | Tensile strength | E-modulus | Elongation |

|---|---|---|---|---|---|---|

|

T |

Rp0.2 |

Rm |

A |

|||

|

°C |

MPa |

MPa |

GPa |

% |

||

|

Heat treated |

Horizontal |

20 |

627 |

956 |

207 |

39 |

|

Vertical |

20 |

626 |

923 |

202 |

43 |

|

|

Heat treated |

Horizontal |

100 |

548 |

878 |

205 |

33 |

|

Vertical |

100 |

546 |

854 |

205 |

36 |

|

|

Heat treated |

Horizontal |

200 |

505 |

823 |

196 |

30 |

|

Vertical |

200 |

504 |

797 |

195 |

31 |

|

|

Heat treated |

Horizontal |

300 |

517 |

857 |

190 |

30 |

|

Vertical |

300 |

505 |

832 |

190 |

32 |

| Condition | Direction | Temperature | Proof strength | Tensile strength | E-modulus | Elongation |

|---|---|---|---|---|---|---|

|

T |

Rp0.2 |

Rm |

A |

|||

|

°F |

ksi |

ksi |

ksi |

% |

||

|

Heat treated |

Horizontal |

68 |

90 |

138 |

30 |

39 |

|

Vertical |

68 |

90 |

133 |

29 |

43 |

|

|

Heat treated |

Horizontal |

212 |

79 |

127 |

30 |

33 |

|

Vertical |

212 |

79 |

123 |

30 |

36 |

|

|

Heat treated |

Horizontal |

392 |

73 |

119 |

28 |

30 |

|

Vertical |

392 |

73 |

116 |

28 |

31 |

|

|

Heat treated |

Horizontal |

572 |

74 |

124 |

28 |

30 |

|

Vertical |

572 |

73 |

121 |

28 |

32 |

Impact strength

| Condition | Direction | Temperature | Impact Energy |

|---|---|---|---|

|

T |

W |

||

|

°C |

J |

||

|

Heat treated |

Horizontal |

-50 |

198 |

|

Vertical |

-50 |

235 |

|

|

Heat treated |

Horizontal |

0 |

237 |

|

Vertical |

0 |

250 |

|

|

Heat treated |

Horizontal |

20 |

242 |

|

Vertical |

20 |

247 |

|

|

Heat treated |

Horizontal |

50 |

248 |

|

Vertical |

50 |

263 |

| Condition | Direction | Temperature | Impact Energy |

|---|---|---|---|

|

T |

W |

||

|

°F |

Ft-lb |

||

|

Heat treated |

Horizontal |

-58 |

146 |

|

Vertical |

-58 |

173 |

|

|

Heat treated |

Horizontal |

32 |

174 |

|

Vertical |

32 |

184 |

|

|

Heat treated |

Horizontal |

68 |

178 |

|

Vertical |

68 |

182 |

|

|

Heat treated |

Horizontal |

122 |

182 |

|

Vertical |

122 |

194 |

Hardness

Typical Vicker’s Hardness levels (ASTM E92, ISO 6507-1, JIS Z2244, GB/T 4340.1), in the L-PBF heat-treated conditions.

| Condition | Condition | |

|---|---|---|

|

HV |

HRC |

|

|

Heat treated |

282±8 |

29±1 |

Surface roughness

|

Condition |

Surface Roughness | ||

|---|---|---|---|

|

Ra |

Rz |

Sa |

|

|

µm |

µm |

µm |

|

|

Blasted |

1,6 |

7,02 |

4,8 |

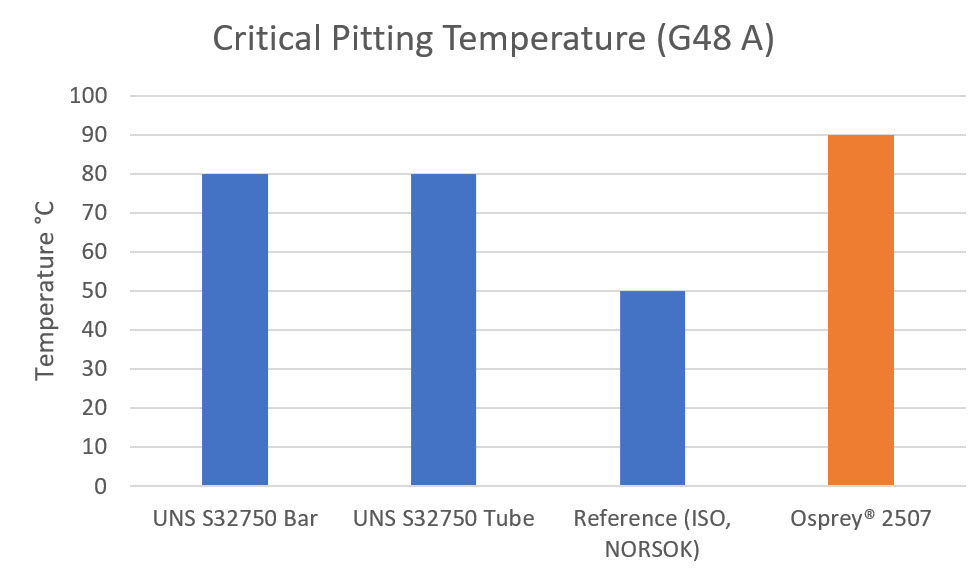

Corrosion properties

Corrosion properties

Corrosion properties tested on the bulk material as per the following standards.

|

Condition |

Critical Pitting Temperature | |

|---|---|---|

|

ASTM G48 |

ASTM G150 |

|

|

°C |

°C |

|

|

Heat Treated |

90 |

>95 |

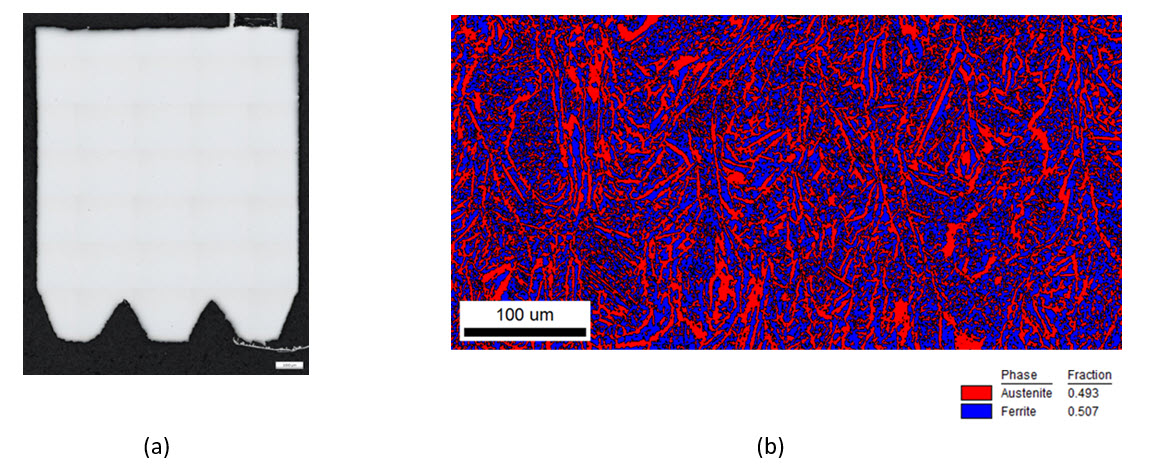

Microstructure

A suitable heat treatment is carried out on the as-built parts in order to achieve the desired austenitic and ferritic microstructure in the final parts. Typically solution annealing between 1040-1110 °C followed by air or water cooling is performed.

Application areas

Typical applications areas for Osprey® 2507 metal powder are components used in, for example, the following industries:

- Oil and gas industry (e.g. impellers, propellers, connecting valves)

- Pulp and paper industry

- Chemical industry

- Refineries and petrochemical plants

- On-shore and off-shore industry